How To Select your Cantilever Gate

Below is an extensive cantilever gate guide created to help you in selecting the perfect cantilever gate for your project. This guide covers the many types of cantilever gates as well as factors for you to consider when selecting a cantilever gate that fits your needs. If you need assistance in deciding if you need a cantilever or a different type of gate, check out America’s Gate Company’s article on how to select your gate.

CANTILEVER GATE OVERVIEW

A Cantilever gate is an excellent choice for both security and aesthetics. Since a cantilever gate slides along tracks rather than swinging out, it is perfect for vehicular access as vehicles do not need to leave room for the gate to swing in an arc. Cantilever gates can have ornamental picket styles with thousands of detail choices or a simple chain link fabric infill. Gate frames may be round or square and they can be fabricated out of aluminum or steel.

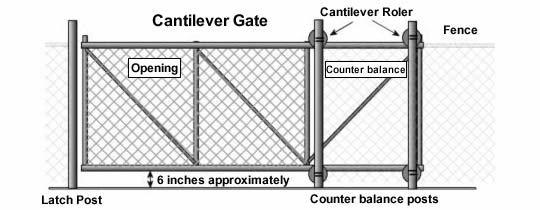

Cantilever gates must be fabricated with a counterbalance that is at least 50% the size of the opening, making the entire gate 50% larger than the opening. The gate will hang from at least two mounting posts and will need one latch post. The mounting posts are typically spaced equal to 50% of the gate’s opening or on either side of the counterbalance section. There must be a free area on one side of the gate that is 1.5x the length of the opening to allow the gate to freely slide and be stored in the fully open position. However, the gate can run parrel to a structure like a fence or a wall. For larger openings, some users prefer to use bi-parting gates, rather than a single cantilever gate. Bi-parting gates are cantilever gates that meet in the middle of an opening and slide in both directions. For a bi-parting cantilever gate, both sides will need a counterbalance.

Unlike some rolling gates, a cantilever gate will hang approximately 6 inches off the ground and does not come into contact with the ground at any time or utilize a wheel that rolls across the ground. Instead, the gate is suspended by several rollers, called trucks, attached to the support posts on one side. It is imperative to use a reputable cantilever gate manufacture to ensure the gate frame is constructed adequately to withstand wear, wind, sag, and gravity.

Cantilever gates are an excellent choice for automation and access controls. For gate automation, the installation will need to be level and the gate will need to be able to freely slide in both directions with no obstacles or obstructions. Along with gate automation that simply allows the gate to slide, access controls are a common feature of operated cantilever slide gates. Some access control features that are common for cantilever gates include keypads, telephone entry, car remotes, intercom systems, reversing sensors, and anti-tailgate sensors. For automated chain link gates, chain link

mesh should be stretched across the entire gate, including the counterbalance. For picketed, ornamental operated gates, the pickets should not exceed a 2 ¼” spacing from inside to inside of picket. The pickets will also need to span the entire gate, including the counterbalance. For a non-automated gate, the counterbalance can remain free of fabric or pickets. Automated or operated gates should comply completely with ASTM and UL-325 standards.

When selecting a cantilever gate, there are two main factors to consider:

- Storage for the gate – Industrial and commercial cantilever gates will be 50% larger than the distance of the gate opening. meaning, a 22’ opening would require a 33’ overall gate width. The added 11’ of gate width is referred to as the counterbalance or the tail. It is imperative to evaluate the details of your installation site to ensure you have adequate room for the entire gate width to open and shut freely.

- Elevations -Commercial and industrial cantilever gates should be installed across a level surface to be in accordance with safety standards and codes. This is for practical safety and usage as a cantilever gate will roll downhill if not installed on a level site. Be sure to check all elevations of the finished grade of the entire length the gate will travel, from the edge of the cantilever gate in the closed position to the edge of the tail section in the fully open position. Use the highest elevation as a benchmark as the cantilever gate is typically set two inches above the highest elevation at a minimum. If the highest benchmark elevation is beneath the tail section and the ground slopes down across the opening, there will be a large space under the gate in the closed position.

CANTILEVER GATE ADVANTAGES

- Price – When comparing an operated double drive swing gate and a typical operator cantilever gate, the cantilever will require fewer operators. Gate automation and operators can be expensive, especially when using a heavy gate framework. There are also many safety devices such as loops, loop detectors, photobeams, etc. associated with an operated swing gate required to ensure it does not close on a vehicle. Far less safety equipment is required for a typical cantilever gate due to the lack of a swinging arc.

- Space – A double swing gate will require a good deal of space across the opening as it will swing 90 degrees. A cantilever gate will allow the gate to run parallel to adjoining structures. This efficient use of space requires less room to move and gives vehicles more room to operate. This is a perfect option for adjoining with a security fence.

- Aesthetics – Cantilever gates have a wide variety of infill options to improve the aesthetics of a secure area. The sleek profile and efficient movement make cantilever gates an aesthetically impressive choice for high traffic entrances.

- Maintenance and Adjustability – Compared to swing gates, cantilever gates require far less maintenance and can be adjusted more easily. The gate is bolted to the posts, making adjustments possible if needed. Swing gates are typically welded to hinges, making adjustment more difficult. Swing gate hinges will also require frequent greasing and can rust. Cantilever gates can be installed with nylon rollers, making grease unnecessary and protecting from rust. There is a long lifespan associated with cantilever gates as there is no portion touching the ground. A correctly installed cantilever gate has very little wear on the trucks and frame and almost zero wear on the gate infill.

INFILL OPTIONS FOR CANTILEVER GATES

The next consideration you should have is the design factors for your cantilever gate. First, you should consider which infill type you should use. This will dictate what materials are used and how your gate operators. Below is an in-depth overview of each design type. America’s Gate Company has free CAD drawings and specifications available for download for all of the styles listed below.

Ornamental

A common design for upgrading aesthetics is the ornamental cantilever gate. Ornamental cantilever gates feature vertical pickets set into the gate frame across the opening and across the tail if the gate is operated. Typically, these pickets will be ¾” or 1” square. If the gate is operated, pickets will be spaced no more than 2 ¼” apart throughout the gate opening and tail to remain in accordance with UL325 and ASTM A2200. Pickets should not be extended through the bottom rail, meaning the bottom rail will be flush. You can choose several stylistic options such as extending the pickets above the top rail, adding an ornate top to the pickets, and adding adornments and extra ornamental rails within the gate infill.

Decorative

If you are looking for a cantilever gate with an ornate infill that does not include pickets, a decorative cantilever gate may be the option for you. This may include wood or metal slats, louvers, perforated metals, and the like. Decorative cantilever gates are in a different category than ornamental gates due to the weight and wind load concerns associated with mixing infill materials. Wind loads and weight concerns are not an issue for ornamental cantilever gates with pickets, so if these situations raise concerns for your site, an ornamental infill may be the best option. Like ornamental cantilever gates, any gaps in the infill should be 2 ¼” or less to meet safety codes.

Chain Link

Chain link cantilever gates are the most popular option in industrial applications and are the most widely used cantilever gates. Chain link cantilevers can use a typical galvanized fabric with a mill finish or a vinyl-coated fabric that is typically black. Again, if a chain link cantilever gate is to be operated, there should be no gaps greater than 2 ¼” throughout the entire gate to meet all associated codes. This includes the tail, meaning the fabric will need to be stretched through the tail as well. For a typical chain link cantilever gate, wind loads and weight are not an issue as the chain link infill features a 98% openness.

High Security

High security cantilever gates utilize solid surface or anti-climb infills and attachments. High security cantilever gates are a common choice for secure and private facilities. They are fabricated to remain as close to the ground as possible while typically being taller than an ordinary gate. The anti-climb wire mesh infill used is tightly woven to prevent any entry and barbed wire is often fixed to the top profile. The wire mesh or solid surface used for high security cantilever gates are often denser and heavier than a typical chain link infill, so wind loads and weight should be considered. Like all cantilever gates, a high security cantilever gate should be installed level, meaning attention should be paid to the grade as these gates are not high off the ground. A level grade is ideal as you do not want large gaps or for the gate to bottom out.

Gate Opening

After choosing the design and overall intent of your cantilever gate, you must consider the structural elements and performance factors that are influenced or changed by your design choices. The single most important factor in the overall design of your cantilever gate is the opening width. A cantilever gate’s opening width, and the infill materials used, are the greatest influence on the style of structural gate framework needed to support the gate’s weight and wind load without issue.

Single Track Gates

A commercial or industrial cantilever gate with an opening less than 27’ and ornamental pickets or chain link infill may utilize a single track. Single track commercial and industrial cantilever slide gates fabricated out of aluminum use a single track system built into the aluminum framework of the gate making it the most budget-friendly option. There are two common options for single track slide gates:

- Inline cantilever slide gates feature a track attached to the face of the gate. The support posts for the trucks are set into the fence line allowing the gate to slide freely behind the fence.

- Offset cantilever slide gates attach the track to the back of the gate, meaning the support posts will be behind the gate. The support posts are not part of the fence line.

Double Track Gates

Ornamental or chain link cantilever slide gates that have an opening of 27’ or more, or a decorative gate with a heavy infill, will need to be a double track gate. Double track

industrial and commercial cantilever gates incorporate two tracks into the aluminum gate framework with one track on either side of the gate frame at the top.

A double track slide gate will need four support posts, utilizing two on either side of the gate to support the trucks. The support posts and trucks add extra support for the gate’s weight, as a double track slide gate has a significantly wider structural profile. A double track gate’s wider profile provides excellent support for wind loading.

Modified Double Track Gates

A typical double track cantilever gate can be modified for larger applications, heavy decorative gates, and large openings. The horizontal profile of a standard double track slide gate can be widened by adding structural profiles to the upper track assembly and spreading the tracks farther apart. An extra wide lower guide track can also be used for a larger opening.

For a standard industrial or commercial double track slide gate, the width is approximately 10” at the upper track assembly. A double track cantilever gate that is modified can range from 12” to 16” at the upper track. Normally for a double track cantilever gate, the width at the lower guide track is 5”. This can be modified to a width of 8”. The lower and upper gate members being wider will help provide structural support for wind loads on the gate.

For double track slide gates that are modified, there are not necessarily standard designs. The gate fabricator should engineer the modifications to a cantilever gate and implement modifications based on the design, weight loads, and wind loading of the gate.

Box Cantilever Gates

The design of a box framed cantilever slide gate is based on the design elements of a standard truss system. Essentially, a box cantilever gate is two, equal cantilever gates, that mirror image each other, approximately 24” apart. Truss members are attached between the cantilever gate panels to create a series of diagonal trusses.

A box cantilever gate utilizes four truss systems that create a rigid framework to account for a heavy load and/or high winds. This design is much like a typical steel building ceiling truss. Box framed slide gates are normally used when opaque materials are attached across the opening of the gate or when there is a large opening in excess of 50’.

Gate Height

Though a cantilever gate’s height is not as important as the gate opening in terms of structural design, height does significantly impact certain design factors. The greatest consideration for gate height is the wind loading. A taller gate will bear more wind load on it’s face than a shorter gate. The following is the performance criteria that should be considered when decided a cantilever gate’s height:

Infill Materials

For industrial and commercial slide gates greater than 6’ in height and utilizing solid infill materials, the gate frame design may need to be re-evaluated. Impacts of high winds on a gate with a solid surface face may be destructive, regardless of whether the gate uses a single or double track. When using opaque or solid materials on the gate face, a designer should consider using a box cantilever gate frame regardless of the opening size.

Consider allowing opening in the face, using welded wire mesh, or a perforated sheet as an infill for the gate to relieve wind-loading pressure. A common practice for relieving

wind loading pressure of an opaque face cantilever gate is a decorative cut out like trees, birds, or a mountain scene.

Gate Support Posts and Footings

For a commercial or industrial cantilever gate, the footing and post size should be based on the overall size and weight of your gate. However, if you are using a taller gate, there is more load-bearing on the gate posts. With taller gate posts, the wind has more leverage and will increase the wind loading.

Standard cantilever gates that are 8’ tall or less typically use 4” O.D. ASTN 1043 gate posts regardless of the gate’s length. This is due to the majority of weight load being placed on the posts not being a cantilevered load. Instead, it is a load that is pushing, pulling, and stressing the tensile strength of the posts. For cantilever gates that are 10’ or taller, a designer may consider using 6-5/8” O.D schedule 40 posts to mitigate the cantilevered load being placed on the gate and the stress on the tensile strength.

Cantilever Gate Hardware

Cantilever gates feature standard gate hardware regardless of the weight, height, and width of the slide gate. However, if the gate has an enclosed aluminum track or a tubular steel gate with external rollers, the hardware is less standard and more specific. Also, when a gate’s weight exceeds 2,000 LBS, heavy duty, non-standard hardware may be considered. The rollers or truckers that support the gate’s weight while allowing it to roll freely may need to be re-evaluated. The guides, trucks, rollers, and gate hardware should appropriately match the weight, type, and size of the cantilever gate, regardless of application.

Gate Weight

Typically, cantilever slide gates do not exceed 2,000 LBS. Atypical, extremely heavy gates are usually the result of openings larger than 30’ or the use of heavy, decorative solid infill materials across the gate of the gate. The following should be considered for exceedingly heavy gates.

Single or Double Tracks

Enclosed aluminum track slide gates come in single and double track options. A double track gate is an excellent choice for longer and heavier gates because double tracks spread the weight load across four truck assemblies rather than the two that are used for a single-track system. Any opening that exceeds 27’ in width will typically require a double track design.

Gate Truss Design

Commercial and industrial cantilever gates are fabricated with a standard diagonal truss system across the length of the gate to support the cantilevered gate load. The diagonal trussing used is similar to a bridge or building design where diagonal members are attached between vertical members.

Top and bottom horizontal support tracks are used where the vertical members intersect. This pattern of horizontal, vertical, and diagonal supports creates a series of connected squares. These squares are prevented from separating or being pulled out of place by the diagonal members that connect at opposite corners. The only way these squares can be moved out of place is the diagonal members being compressed or stretched.

Normally, a truss gets its structural strength from the tensile strength of metals. The tensile strength of structural metals is in the tens of thousands, so it would take thousands of pounds of force to pull the diagonal truss apart.

If a gate’s framework did not include diagonal members, the squares would simply bend under the force of gravity. This is important considering the cantilevered weight load for most structural metals is in the hundreds of pounds.

Cantilever Strength and Support

Industrial and commercial slide gates’ trussing can be modified to support heavier and longer gates. There is a standard principle that most cantilever gate designs use: A cantilever gate’s vertical support length should be larger than the spacing between each vertical support. Meaning, if the vertical support is 72”, the vertical supports should be 72” or more apart. No matter the height of the gate, the majority of cantilever gates do not exceed 72” between vertical supports.

To allow commercial and industrial slide gates to support heavier and longer gate frames, vertical supports can be closer together, creating a rectangle with the long side being vertical rather than a square. With a rectangular design, the stress on the diagonal truss is lessened.

Weight and Gate Hardware

The majority of cantilever gate hardware for both steel tubular external roller gates and aluminum enclosed track gates are designed to support gates of 2,000 LBS or less for continuous duty. Gates in excess of 2,000 LBS use gate hardware that is considered non-typical and is not readily available.

When designing a gate that utilizes heavy-duty gate hardware to support gates larger than 2,000 LBS, it is important to consider that either an overhead trolley system or a ground-mounted truck assembly is typically used. Both of these options will require significantly modifying the design of a standard slide gate.

Simply adding more gate support posts or rollers when trying to support larger gate openings is not enough. The design of cantilever gates allows the cantilevered section of the gate to be placed evenly between the gate support posts and respective rollers. This design spreads the weight over a wider area. Using additional intermediate support posts and rollers may cause the weight load to be concentrated on a smaller area, which places more resistance on the rollers and can possibly cause the gate frame to fail.

Cantilever Gate Type

There are two structural metal options that are used across the industry when fabricating a cantilever gate. Aluminum and steel are the main metals used in the construction of a cantilever gate but there are more differences than just the metal choice:

Aluminum cantilever gates use extruded aluminum square and rectangular profiles in the design of the gate. Aluminum is often used for wider gate openings.

o The top horizontal member is a combination of custom extruded track and structural member(s). The track is approximately 2 ½” wide by 2 ¾” tall. The trucks (or rollers) run inside the track. The trucks are supported from the bottom of the track rather than hung from the top. This prevents debris and water from settling in the track.

o The bottom horizontal member is a 2” x 2” square tube or a 5” x 2” rectangle tube for larger gate openings. This member serves as the bottom guide and provides structural support for the cantilever gate.

o The vertical gate members are 2” x 2” square tube spaced no farther than 72” apart.

o Diagonal supports sit between the vertical supports. These can be either a 2” square aluminum or cable system.

Cantilever gates utilizing steel usually use round galvanized tubing for the framework. Intermediate bracing and diagonal supports are welded to the framework to improve rigidity and prevent sag over time. Gate rollers made of nylon or steel are attached to the mounting posts. Typically, two will be used at the top track and two at the bottom. The gate is suspended between the top track and bottom track rollers to allow the gate to fully slide to open and close.

o The top and bottom horizontal members are a 2 ½” O.D. tube that run the length of the gate. This member serves as the gate’s top and bottom tracks as well as structural support. The rollers run on the outside of these tracks.

o The vertical gate members are 2” O.D. tube that are spaced no more than 72” apart.

o Between the vertical members are the diagonal supports. On steel cantilever gates, these are typically 1 5/8” O.D. tubing, however, a cable may be substituted.

Aluminum vs Steel

So, how does a designer choose whether to use an aluminum cantilever gate or a steel cantilever gate? Steel cantilever gates are more budget-friendly options and often easier to repair. The rollers and gate hardware are very heavy-duty. Aluminum cantilever gates, which are less economical, offer several more design options:

· Aluminum cantilever track gates are the best choice for decorative and ornamental gate designs due to the enclosed track system and square profiles. The square pickets used as an infill for ornamental gates can be placed between the top and bottom members or can be mounted to the face of the gate. The track may be placed on the inside of the secured area, which hides the track and hardware from the outside and increases the curb appeal of the gate.

· Cantilever gates fabricated out of aluminum are the best choice for a larger opening. The width of the upper and lower horizontal members can be easily extended without interfering with the track design. Additional structural supports or a double track can be easily added.

· Aluminum is almost exclusively used when manufacturing a box cantilever gate. The square profiles make it easy to create a series of trusses by joining profiles with each other. Whereas a steel tube design will require a considerable amount of coping. Most importantly, aluminum is stronger than steel on a pound-per-pound basis. This is an important point to remember when attempting to support a great deal of weight.

Automation

Aluminum and steel cantilever gates are great choices for automation and access controls. Aluminum gates are lighter than steel and will provide more consistent sliding across the travel of the gate due to the truck system and enclosed track having tighter tolerances. When using a very heavy or large gate design, you may consider an aluminum cantilever as it may place less stress on the gate operator or require a smaller gate operator. For openings under 27’ with a standard chain link infill, a steel cantilever is an excellent, economical choice.